Proofing, cooling, buffer.

We plan the process well.

Every step, its machinery.

Swing-trays, shelves for single or in tray products suitable for proofing, cooling or to create buffering systems or trays storage.

Three main groups are:

Proofing Cells – Cooling Cells – Buffer

Proofing Cell

STATIC PROOFER CELL FOR TRAYS’ RACKS (Laminated products, ‘Panettoni’, Colombe’…)

Cell suitable to receive and contains racks with trays in order to allow the proofing process of products inside.

Racks are manually inserted and removed from the cell by means of one or more operators.

Size of cell can vary according to the number of racks necessary for the line production capacity.

Possibility to have one single proofing chamber or more separated proofing chambers.

Structure and edge profiles in stainless steel.

The insulation panels are sandwich type painted steel/PU/painted steel 80 mm thickness.

The ambient inside the proofer is lighted by neon lamps.

Structure with doors to permit the passage of the racks.

Climatization unit for the control of the temperature and humidity inside the proofer chamber, installed on a stainless steel platform.

SWING-TRAYS PROOFING CELL FOR STAND ALONE PRODUCTS OR INSIDE TRAYS.(bread, sandwich, sliced bread…)

Proofing cell with loading of product :

• Stand alone product on a swing tray that could be with plastic mesh moulds or smooth moulds.

• Inside tray on a ‘rack’ swing tray type for loading on a single loading (one floor) or double loading (two floors).

Structure in stainless steel, with no.2 internal aisles (one on each side) to consent complete access to the aerial part of the proofer for cleaning and maintenance.

The two aisles are lighted by neon lamps, and also houses the climatization ducting.

The proofer is fully enclosed with insulation panels.

The air treatment unit (ATU) for the proofer climatization and temperature and humidity control, is

positioned inside the proofer chamber, on a stainless-steel platform with relevant access stair.

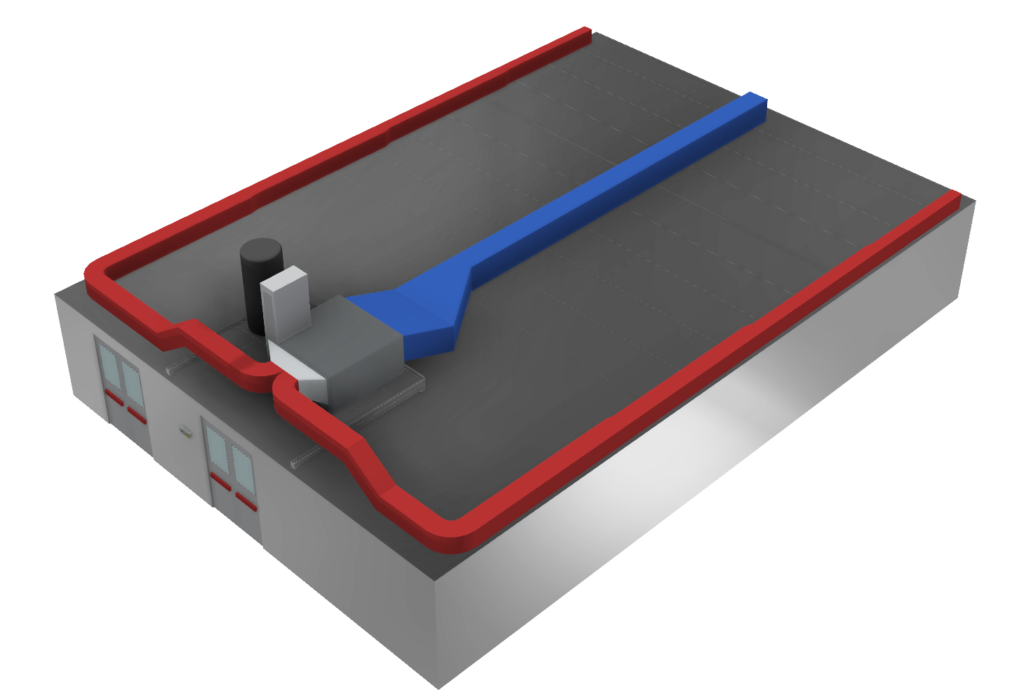

STEP TOWER PROOFING CELL FOR PRODUCTS INSIDE BAKING TRAYS

Unit suitable to receive trays with products to be proofed.

In the loading and unloading zone of cells there are conveyor systems that automatically insert and take out trays.

The tower is divided in two main parts : an ascending section from where trays enter, rise to the top and are moved by a pushing device towards the descending section, from where they finally come out after proofing.

Each part is equipped with a series of trays holder levels, with variable number and size according to the tray used and the required proofing time.

Both sections could be or not thermally insulated with panels and equipped with an air treatment system.

Cooling Cells

(STEP COOLER)

Unit suitable to receive the trays with the products coming from the oven and to cool them through a forced air system.

In the loading and unloading area of the cell, there are respectively conveyors that insert and take out the trays.

The tower is divided in two main parts : an ascending section from where trays enter, rise to the top and are moved by a pushing device towards the descending section, from where they finally come out after cooling.

Each part is equipped with a series of trays holder levels, with variable number and size according to the tray used and the required cooling time.

Both sections could be or not thermally insulated with panels and equipped with an air treatment system (ATU) for the forced air mode.

Buffer / Storage

BUFFER AND STORAGE TOWERS FOR TRAYS

In the loading and unloading area of the cell, there are respectively conveyors that insert and take out trays.

The system is divided into two main parts: an ascending section from where the trays enter, rise to the top and are translated by a pusher with rungs towards the descending section, from where they eventually exit.

Each section is equipped with a series of tray holder shelves, with variable number and dimensions according to the tray used and the production speed.

Video

We will be online soon with videos and animations related to this product category.

Ready to satisfy

your every need.

We project solutions adapted to existing lines or new design according to specific guidelines provided.